工作原理

液/固混合流体通过进料管经布料盘加速均匀分布于离心机转鼓内,在离心力场作用下,通过滤片截留固相,滤出液相。持续进料,直至料满,停止进料,如工艺需要时则对滤饼进行洗涤、提纯,同时将洗涤液滤出。进一步脱液,直至达到分离要求。降至低速,刮刀将大部分滤饼刮下,抻袋装置将残余滤饼卸出,完成一次工作循环。

Operating principle

The mixture of solid and liquid is distributed uniformly&quickly in centrifuge drum by feeding tube and distributing evenly through the distributing disk. acting on the centrifugal position. Liquid-solid mixed fluid intercept the solid phase through the fitter to filter out the liquid phase. Centrifuge continues to feed until full. Then stop. Solid cake is rinsed and purified when the process requires. And the rinsing liquid is filtered out meanwhile. Centrifuge further filter until the separation requirements are met.

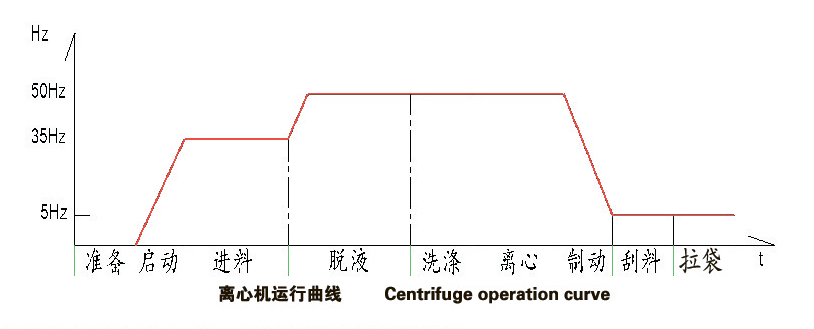

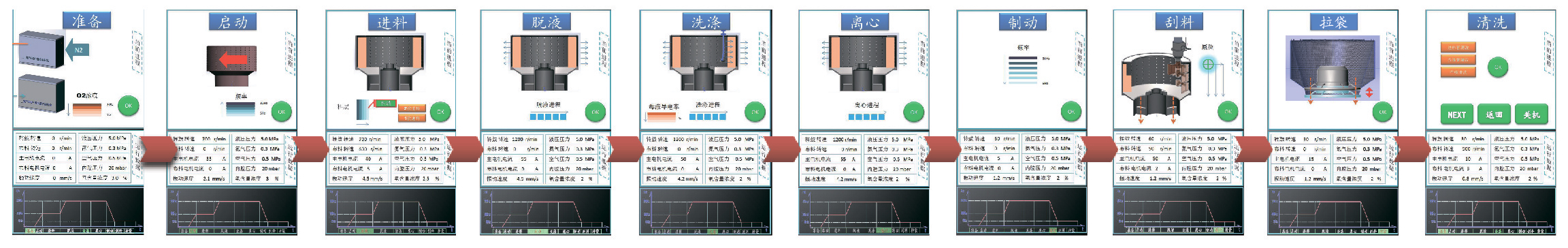

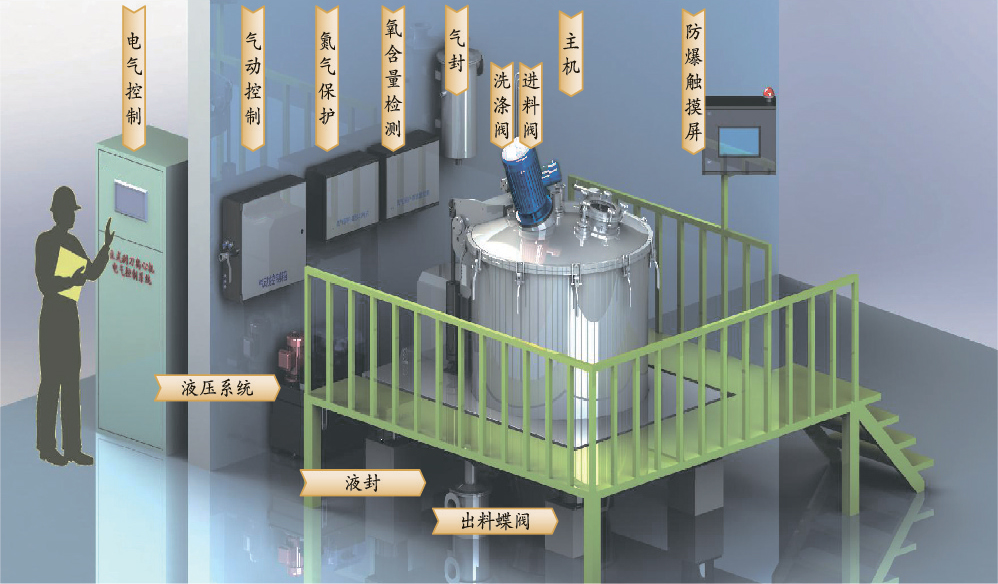

控制过程

离心机运行由PLC控制,系统按预设运行程序自动运行。不同的机型有相应的运行参数或调整范围,对特定的工况在调试和后续的

运行中设定合适的运行参数,以满足分离要求。控制系统对实际运行过程中的过载进行自动修复或保护。

自动控制系统对离心机主机、液压系统、气动系统、氮气保护系统、阀门以及与离心机相关的泵、阀、物料输送系统等进行控制。

Control Process

The operation of centrifuge is controlled by PLC. The system runs automatically according to the preset program. Different centrifuges have corresponding operating parameters or range of adjustment.

In order to meet the requirements of separation. appropriate operation parameters are set for specific conditions

in debugging and subsequent operation. The control system can automatically repair or protect the overload in the actual operation.

Automatic control system controls centrifuge mainframe, hydraulic system, pneumatic system, N2 protection system,and pump, valve, material conveying system related with centrifuge, etc.

离心机运行过程以及控制。Operation and control process of centrifuge

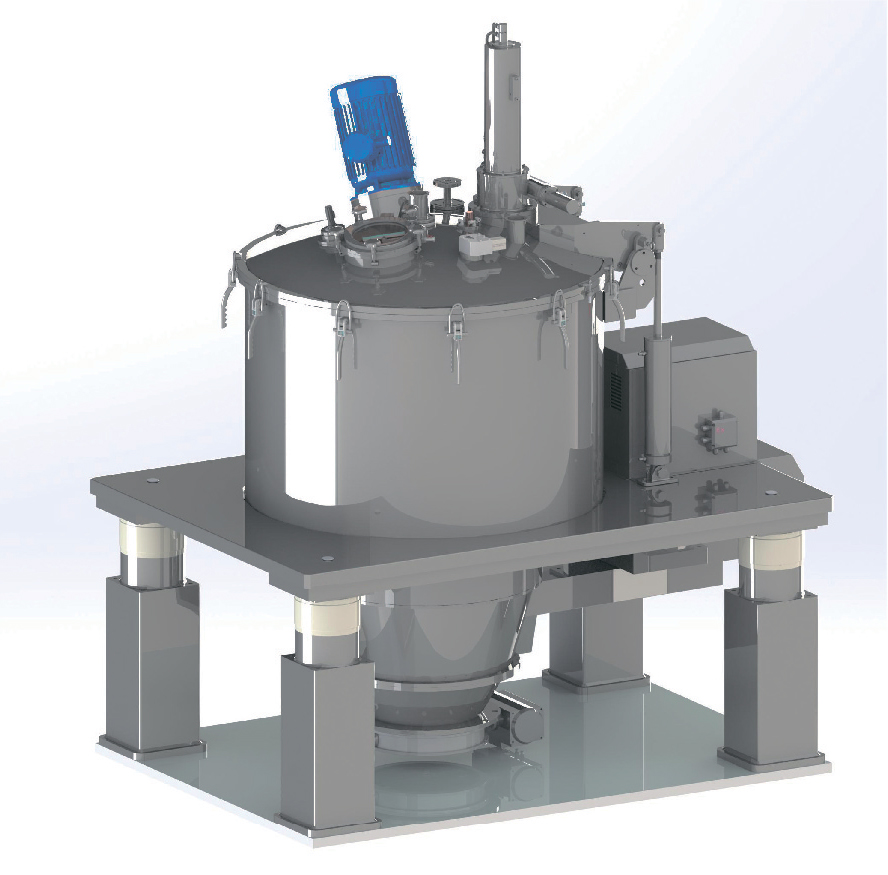

PLD平板拉袋卸料离心机

PLD plant bag-pulling scraper discharge centrifuge

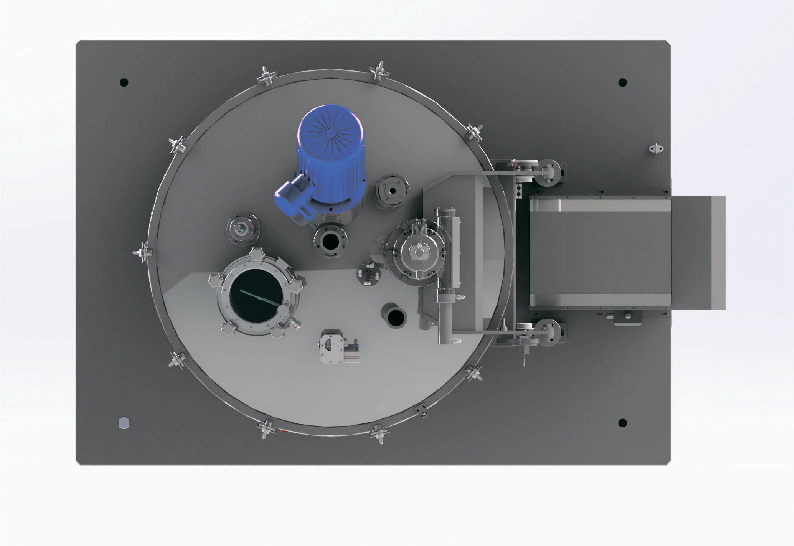

PLD上盖布置图

PLD Top cover diagram

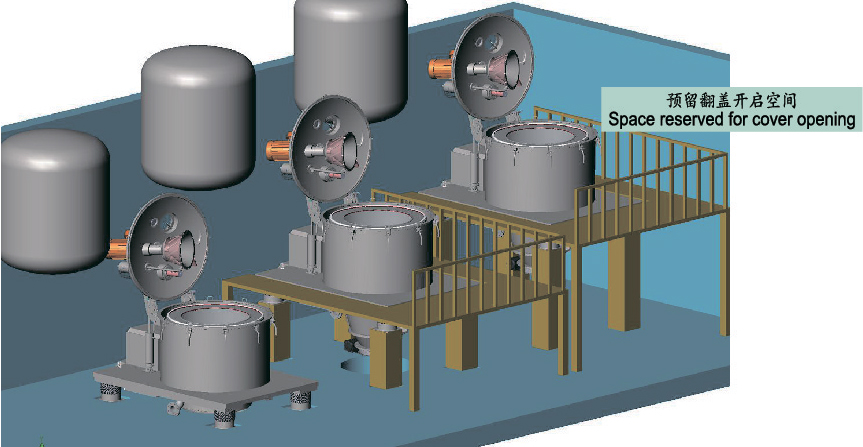

系统集成

System integration

XINGYI控制自动化、智能化,可实现远程控制、无人化车间

XINGYI全密闭,满足环保闭式生产要求

XINGYI Automatic and intelligent control, remote control and unmanned workshop

XINGYI Fully enclosed, satisfying environmental requirement on closed loop production

个性化配置

Personal configuration

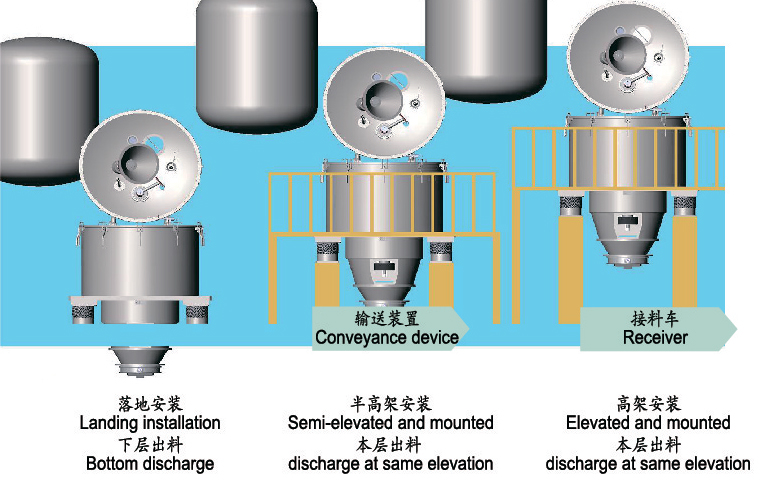

安装

u 安全性:满足动、静载荷承载强度;满足减振与隔振要求;满足操作与检修安全。

u 方便性:满足操作方便性和检修的方便性

u 经济性:满足工艺链的合理性,减少物流周转环节和降低运行成本

u 提供安装基础图及相关技术支持

Installation

u Safety: satisfy requirements on dynamic and static loading capacity, shock absorption and isolation, operation and maintenance

u Convenience: Meet the convenience of operation and maintenance

u Economical: Meet the rationality of process chain, reduce logistics turnover link and reduce operation cost

u Provide installation foundation draws and related technical supports.

主要特性

u 平板结构,液态阻尼减振,无基础安装

u 大翻盖或全翻盖形式

u 斜盘布料,可调式进料装置,改善布料平衡

u 上置式抻袋装置清除残余滤饼

u 料层厚度设定+料层探测+n次补料,确保滤饼层厚度

u 滤饼不平衡自动修复+过振动待机保护

u 雾化洗涤,洗涤定量控制,间隙式/脉冲洗涤。洗涤滤液导电率检测+出液转换

u 高精度转鼓(机加工、平衡),高分离因数,提高分离效率

u 设置主轴封、刮刀轴封、布料轴封,轴封压力比内腔高20mbar,废气有序排放

u 联组传动带

u 内置式测速传感器

u 外置补油装置(手动/自动)

u 数字控制无级分层刮料,堵转自动修复

u 刮刀刀片耐磨设计与防污染设计

u 全密闭液压站,不锈钢液压油箱

u 自动清洗程序

u 系统全密闭,满足清洁生产要求

u 电脑、手机APP远程监控系统

u 多重保护:

过振动保护,开盖保护+合盖保护,

电机过载保护,料位保护,刮刀原位保护,

抻袋支架原位保护,工序联动机械+电气保护,

氮气保护,静电接地保护,检修锁定保护,

故障诊断与待机保护

Main features

u Flat plant structure, liquid damping, no foundation mounting

u Large or fully hinged cover form

u declining feeding disk .Adjustable feed device to improve distribution balance

u Removal of residual filter cake by top bag pulling device

u Setting material thickness+Layer detection+N secondary feed. Ensure fitter cake thickness

u Automatic repair of filter cake imbalance+Over-vibration standby protection

u Atomization washing. Washing quantitative control. Clearance/pulse washing. Detection of conductivity of washing filtrate+Liquid output conversion.

u High precision drum (machining and balance), high separation factor, improved separation efficiency

u Set Spindle Seal, scraper Shaft Seal, feed disk Seal.Axial seal pressure higher than inner cavity 20mbar. Exhaust gas orderly emission.

u Joint drive belt

u Built-in speed sensor

u External oil supplement (manual/automatic)

u Digital control stepless layer scraper, plug rotation automatic repair

u Scraper blade wear-resistance and pollution-proof design

u Fully enclosed hydraulic station, Stainless steel hydraulic tank

u Automatic cleaning program

u Fully enclosed system satisfying specification of pharma production

u Computer, mobile phone APP remote monitoring system

u Multiple layers of protection

Over-vibration protection, cover opening and closing protection

Motor overload protection, Material level protection, scrapper normal position protection. In situ protection of bag pulling support. Process linkage, Mechanical and electrical protection.

N2 protection, Electrostatic grounding protection.

Overhaul lock protection.

Fault diagnosis and standby Protection

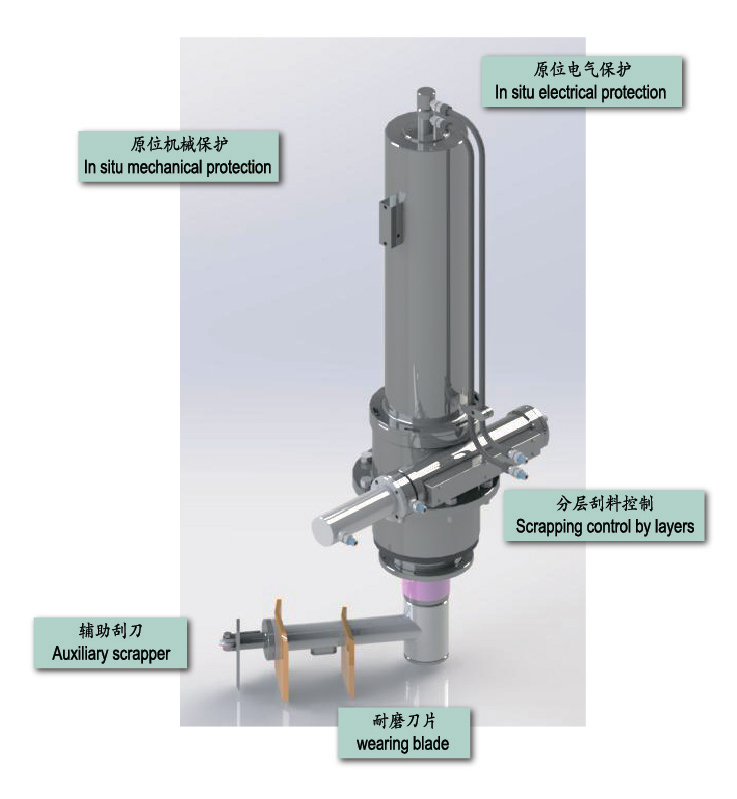

卸料控制

u 无级分层刮料(0-100%可调)

u 卸料堵转自动修复

u 原位保护

u 布料盘防积料

u 刮刀刀片耐磨设计与防污染设计

u 辅助刮刀(适用于LGZ )

Discharge control

u Stepless stratification scrapping (0-100% adjustable)

u Discharge plugging automatic repair

u Normal position protection

u The feed disk prevents the raw material from piling up

u Scrapper blade of wear-resistance and pollution-proof design

u Auxiliary scraper(applicable for LGZ)

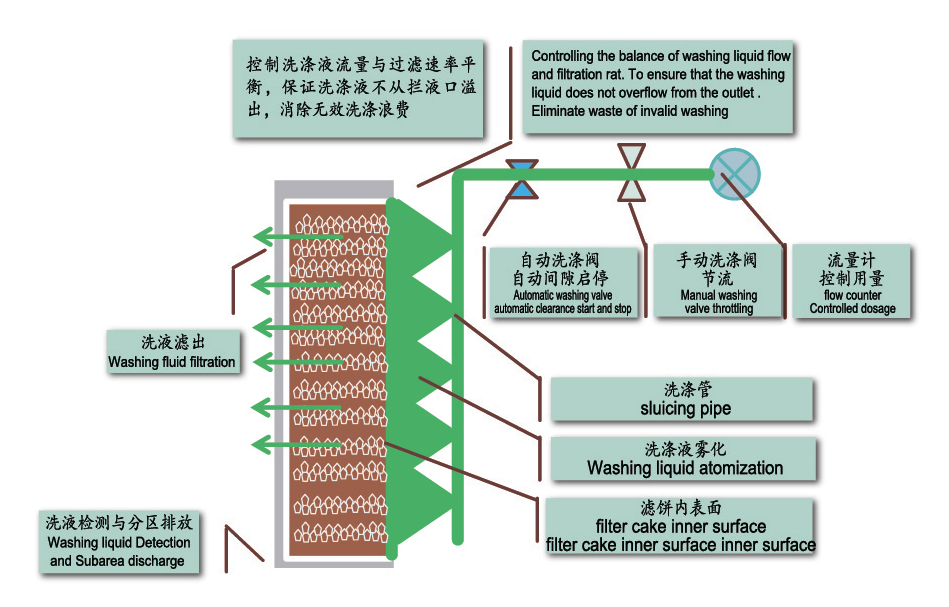

洗涤控制

u 洗涤流量控制(手动阀/流量计+自动阀)

u 间隙式/脉冲洗涤

u 洗涤液定量/定时洗涤

u 洗涤滤液导电率检测+出液转换

u 雾化洗涤

Washing control

u Washing flow control (manual controlled valve/flow meter and automatic valve

u Intermittent/pulse washing

u Washing liquid quantity /Timing washing

u Detection of conductivity of washing filtrate+Liquid output conversion

u Atomization washing

系统配置

u 离心机主机

u 液压系统

u 气动控制系统

u 电气控制系统

u 防爆操作箱/防爆触摸屏

u 氮气保护一氧含量检测

u 氮气保护一氮气置换

u 液封

u 气封

u 出料阀、进料阀、洗涤阀

System configuration

u Main engine of centrifuge

u Hydraulic system

u Pneumatic control system

u Electrical control system

u Ex-proof operating box / Ex-proof touch screen

u N2 protection一oxygen content detection

u N2 protection一N2 replacement

u Liquid seal

u Air seal

u Discharge valve, feed valve, washing valve

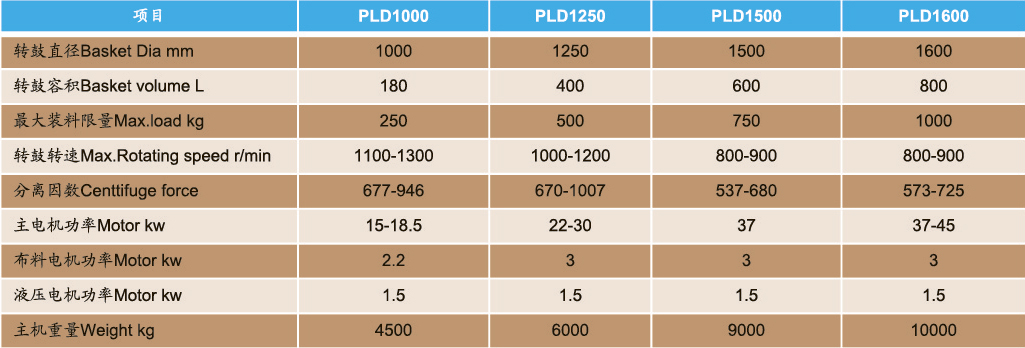

技术参数 Technical parameter

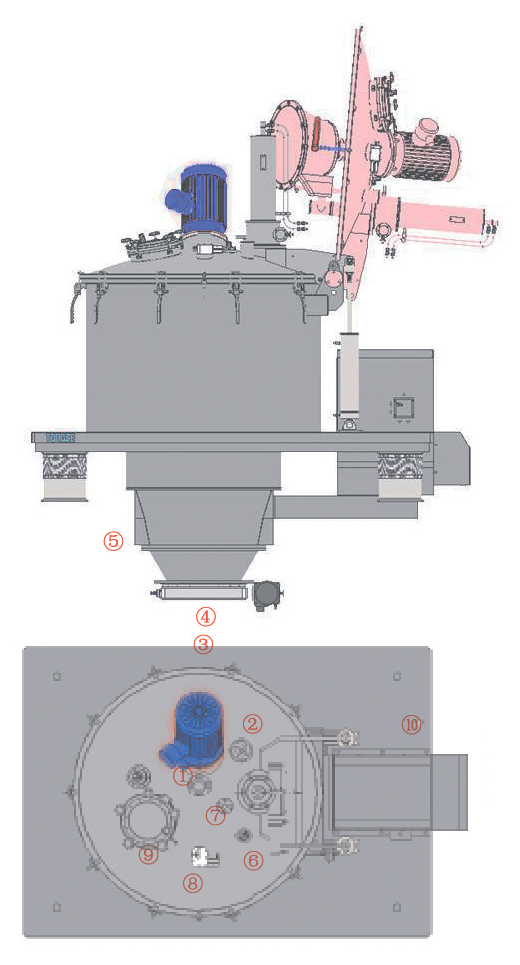

PLD外形简图

接口

1 进料管口

2 洗涤管口

3 出液管口

4 出料口

5 氮气进气口

6 排气口

7 轴封进气口/排气口、测压口

8 料层控制

9 人孔及清洗

10 液压集成接口

Connection interfaces

1 Feed inlet

2 Washing inlet

3 Liquid discharge

4 Solid discharg

5 N2 inlet

6 Exhaust air outlet

7 Shaft seal air inlet/outlet and pressure testing port

8 Material thickness control

9 Manhole and cleaning

10 Hydraulic integrated interface